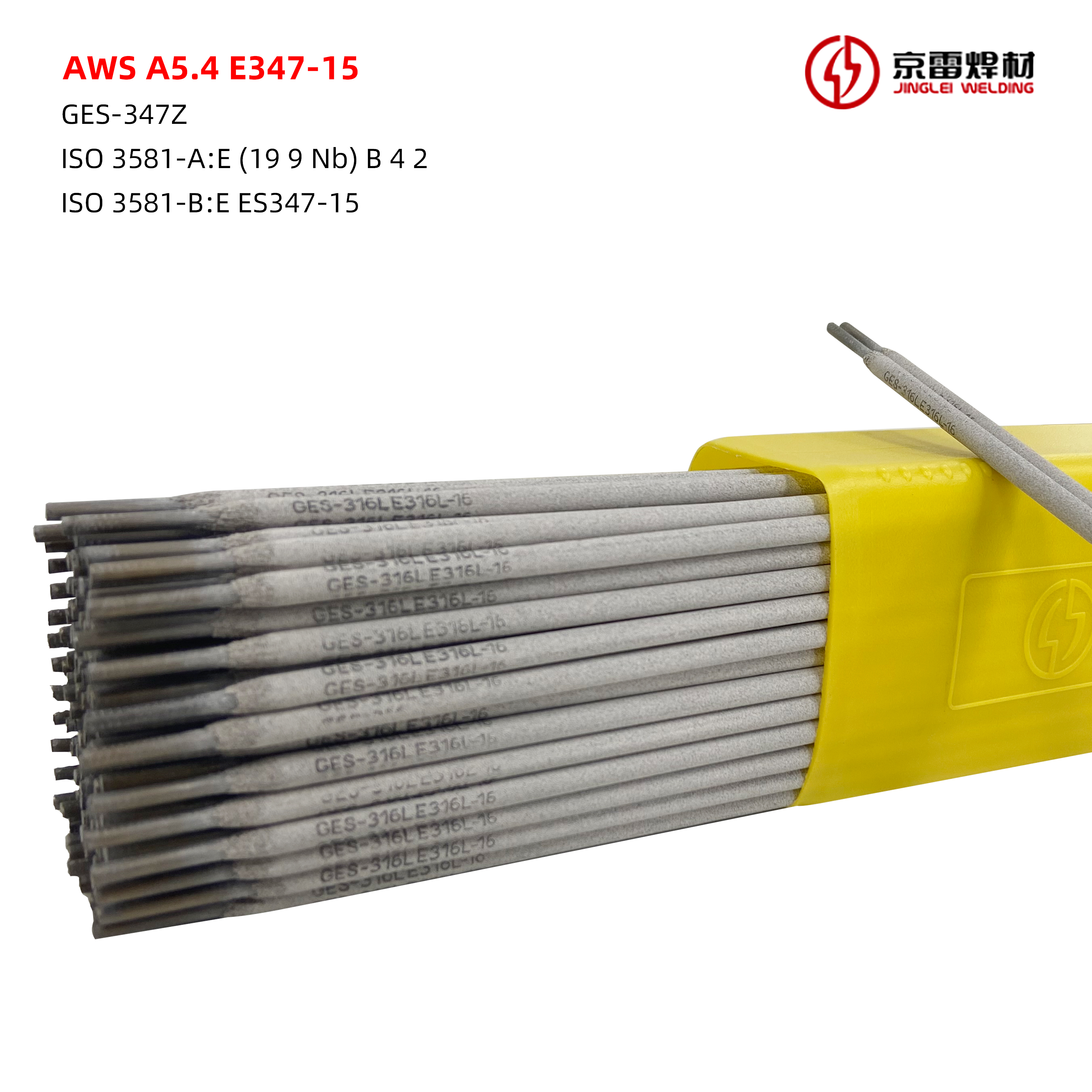

Stainless Steels Manual Electrode E347-15 Polypropylene reactor bona glutino

WELDING technologia

Ne quaestiones

Permanere adero

Arcus instabilitas

Turpis corona

Immodicus inquinatus

Saepe usus est in acido et calore renitens vasorum pressurarum;

petrochemical et aliis momenti structurae ut

1Cr18Ni9Ti(SUS321), 1Cr19Ni11Nb(SUS347).

Praecipua compositio humilis hydrogenii inacta ferro manus electrode est 19%Cr-11%Ni-Nb

Ripple bysso

Addens Nb ex 308 efficaciter potest

meliorem repugnantiam intercrystalline corrosio

Optimum glutino faciendum, egregium incendium resistentia;

porositas bona resistentia, proprietas mechanica stabilis metalli fusilis

facile slagging

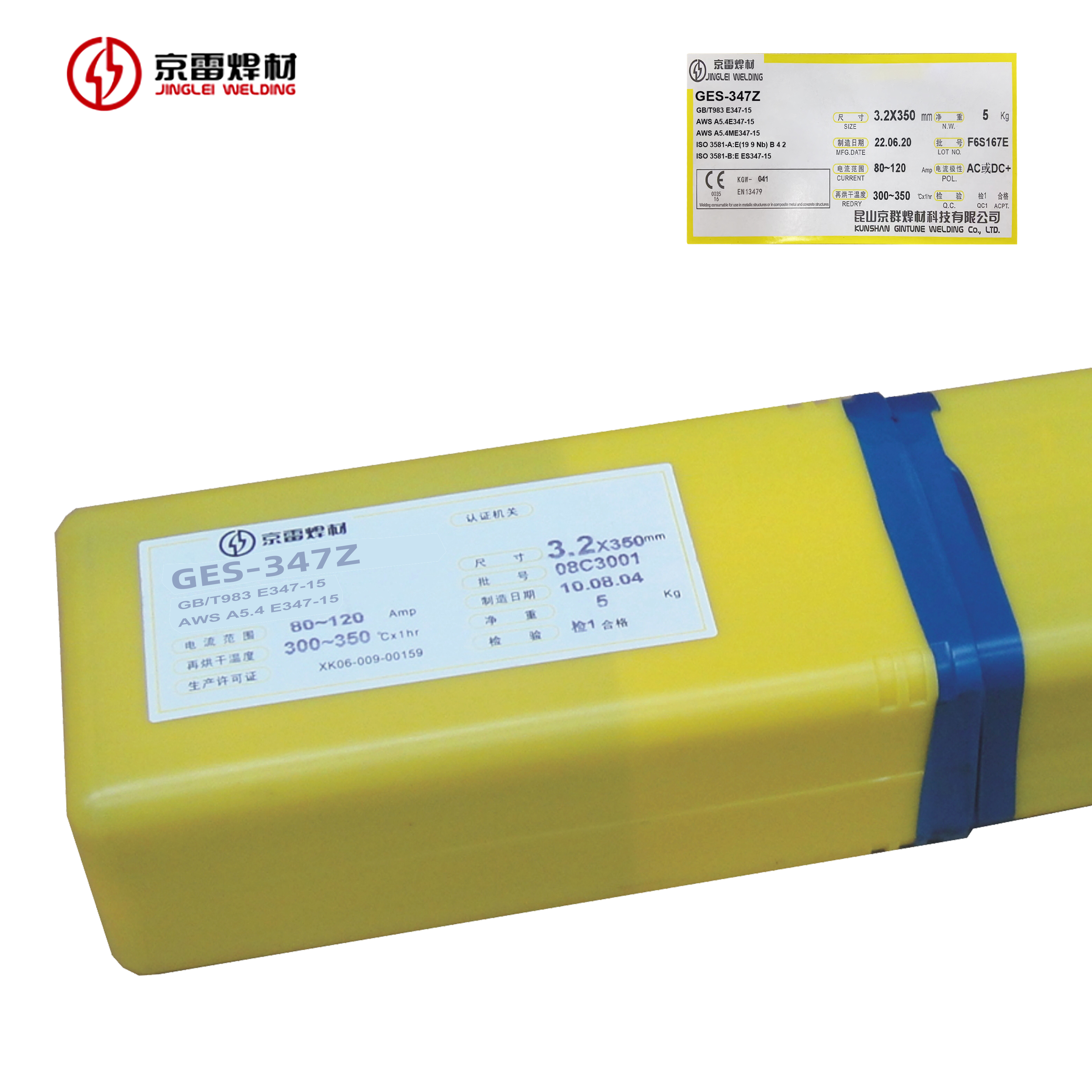

Product Parameter

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Other |

| GB/T REGULAE | 0.04 | 1.68 | 0.75 | 0.27 | 0.005 | 9.4 | 19.5 | 0.24 | 0.11 | Nb:0.42 |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | IMAPACT VALEO J/℃ | Caloris curatio ° C * h * | ||||

| GB/T REGULAE | 640 | 35 | - | - | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W* | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Factory firmamentum

Productum idoneum ad

amplis applications

WELDING technologia

Zhangjiagang CIMC Shengdayin

Cryogenic Equipment Co., LTD.

Vasis cryogenic

(LNG Statione Replens)

Cr-Mo chalybe series materiarum glutino et

electrode glutino materiae surfacing

late in PETROLEUM conflans apparatu

Tianshu Xing, magna liquefactum

naturalis gas (LNG) tabellarius cum

174,000 cubicorum, est

prima navis confici

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Other |

| GB/T REGULAE | 0.04 | 1.68 | 0.75 | 0.27 | 0.005 | 9.4 | 19.5 | 0.24 | 0.11 | Nb:0.42 |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | IMAPACT VALEO J/℃ | Caloris curatio ° C * h * | ||||

| GB/T REGULAE | 640 | 35 | - | - | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W* | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||