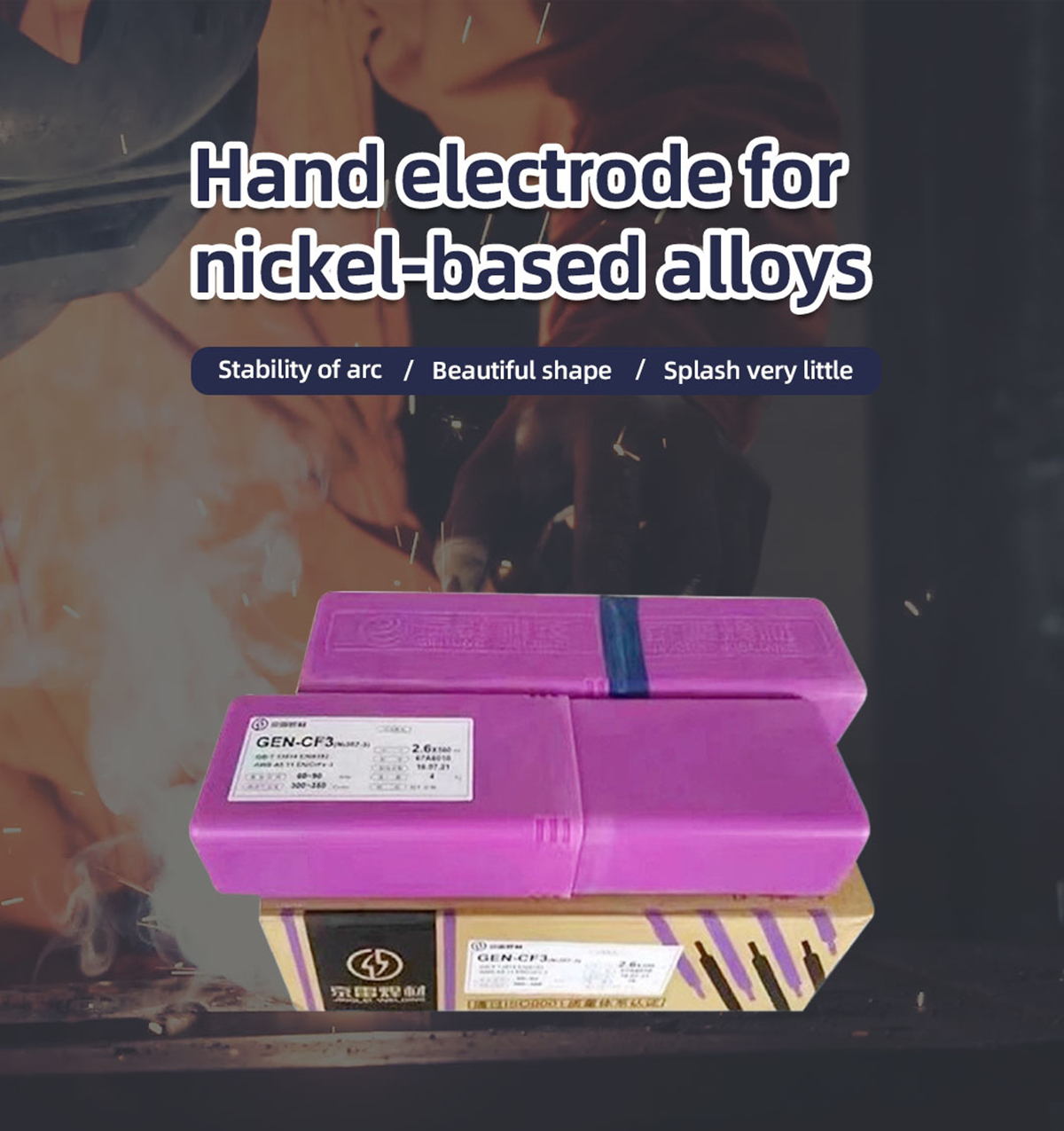

Nickel admixtis EniCrFe-VII EniCrFe Manuale iunctio Welding

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | Cr | Ni | Fe | Nb | Cu | Mo | |

| GB/T REGULAE | 0.05 | 5.00 | 0.80 | 28.0-31.5 | ≥50 | 7.0-12.0 | 1.0-2.5 | 0.50 | 0.50 | |

| AWS Rules | 0.05 | 5.00 | 0.75 | 28.0-31.5 | Margin | 7.0-12.0 | 1.0-2.5 | 0.50 | 0.50 | |

| EXEMPLUM PENSI HABEO | 0.041 | 2.5 | 0.33 | 29.6 | 56.9 | 9 | 1.45 | 0.017 | 0.041 | |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | IMAPACT VALEO J/℃ | PROLATIO(%) | ||||

| GB/T REGULAE | 360 | 550 | - | 27 | ||||

| AWS Rules | - | 550 | - | 30 | ||||

| EXEMPLUM PENSI HABEO | 450 | 650 | - | 41.5 | ||||

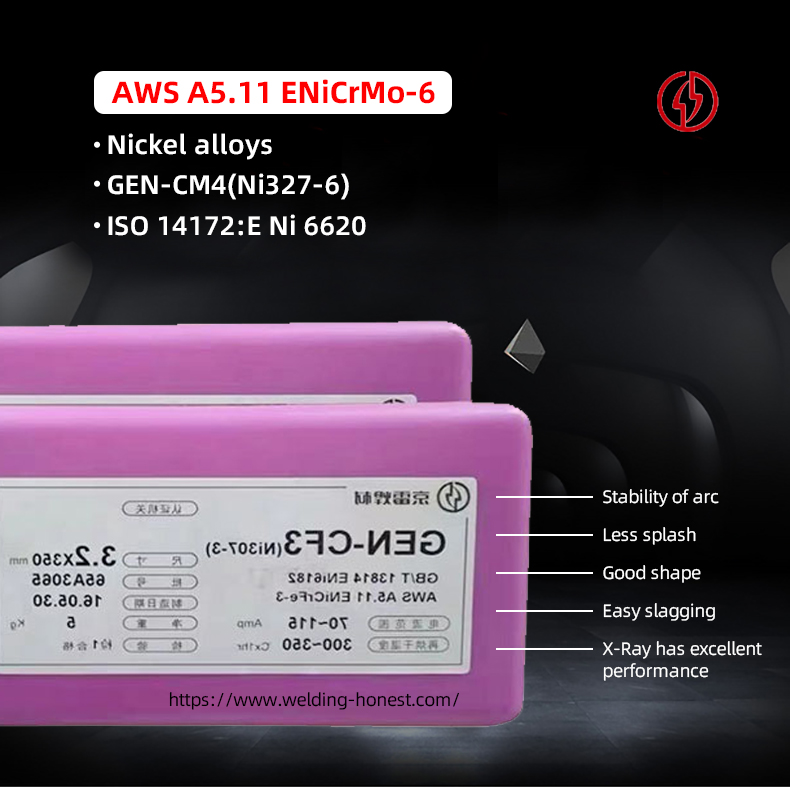

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W* | 55-80 | 65-110 | 80-130 | ||||||||

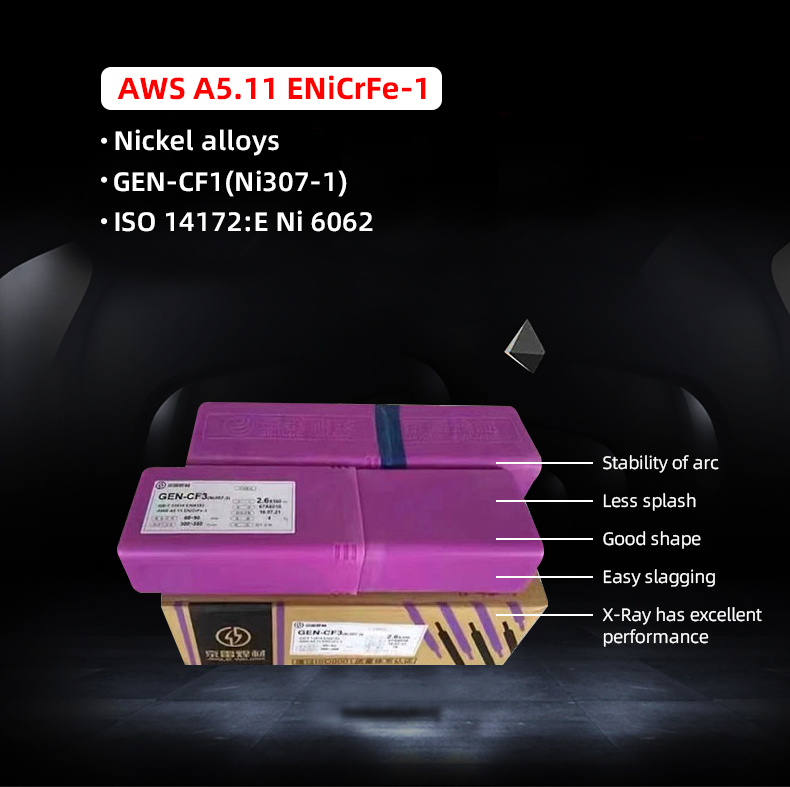

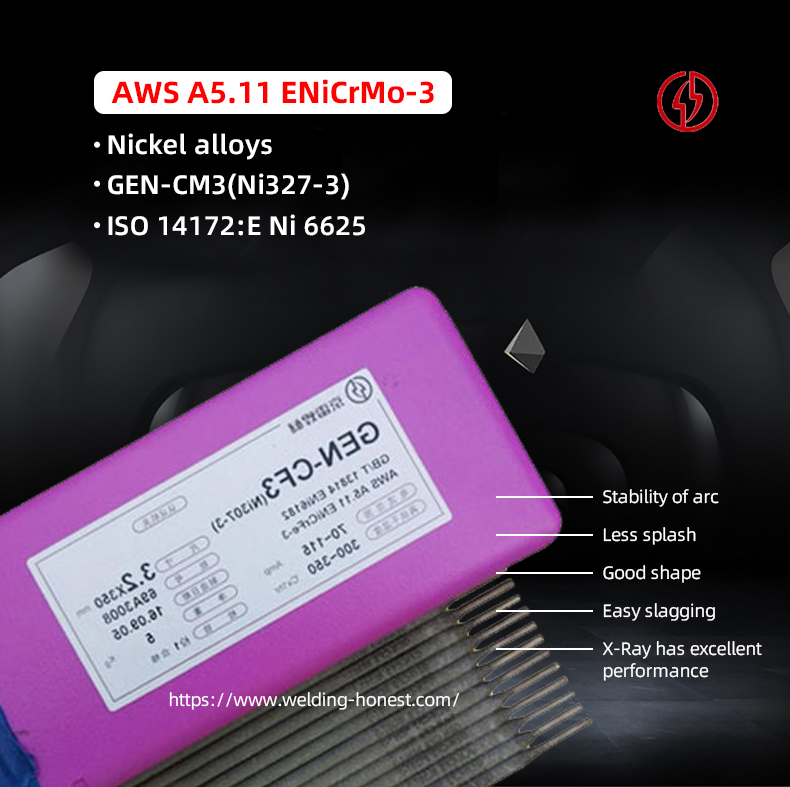

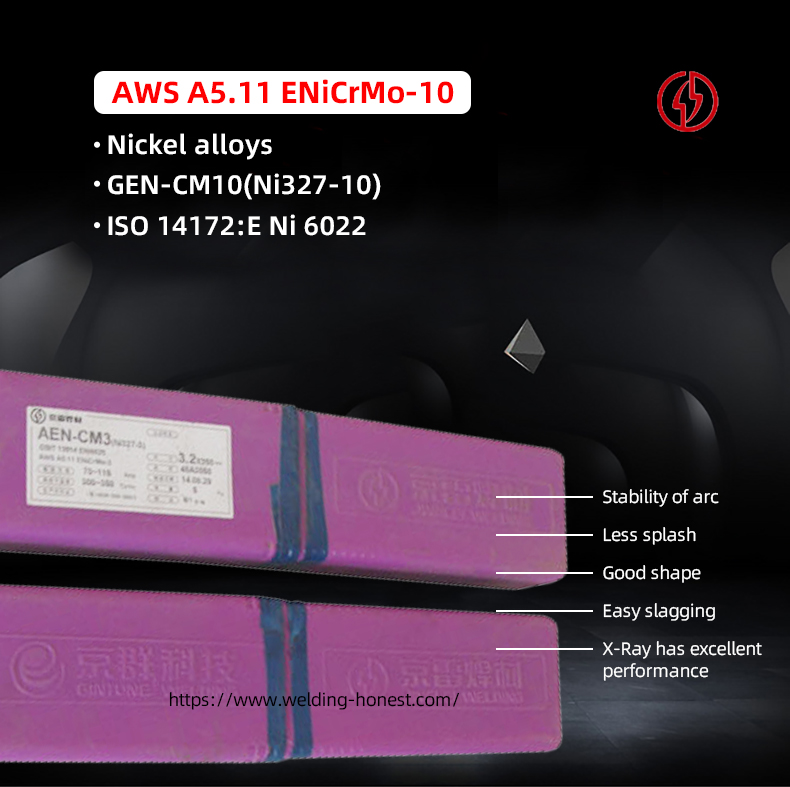

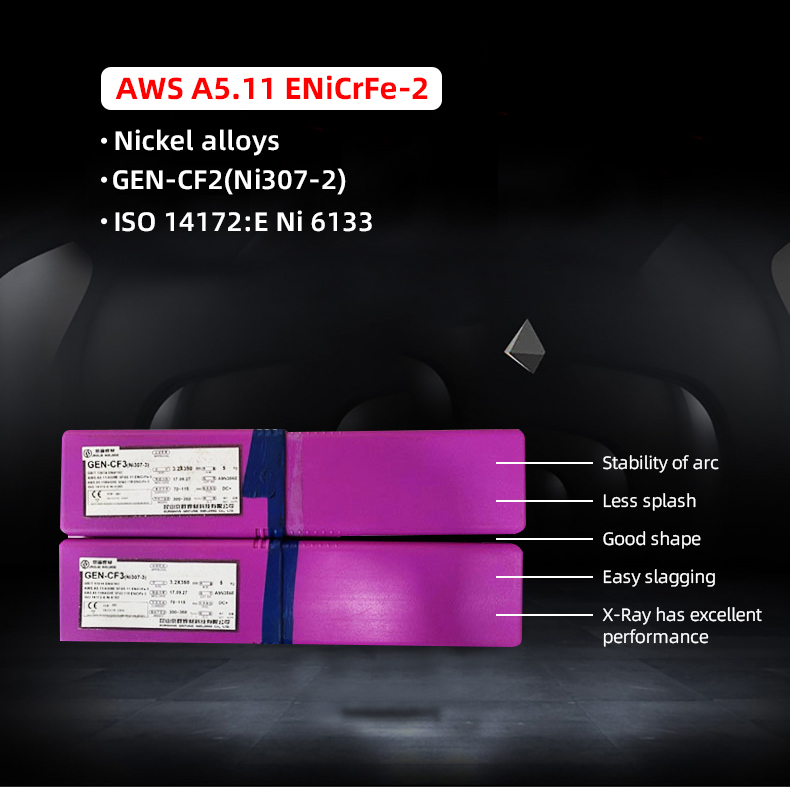

Minimum hydrogenii genus manu electrode, compositio nominalis (pondus percent) est 55Ni-29Cr-9.5Fe-3Mn-1.5Nb+Ta, nickel - chromium - mixtura ferri electrode.

Summus Cr contentum melius efficit repugnantiam ad vim corrosionis creptionis in radiorum nuclei et aquae purae environment.

Arcus stabilis, pulcher formans, parum torsit, facile pigri, resistentia porositas bona, proprietas mechanicae metalli fusilis stabilis, bonaque corrosio resistentia in oxidatione caliditatis et in atmosphaerae sulphuris continentis.

-

Sinopec eleganter et chemical Project

-

Haman Huasheng phenol recuperare turrim

-

chalybeum, intemerata chalybea turris, welding

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | Cr | Ni | Fe | Nb | Cu | Mo | |

| GB/T REGULAE | 0.05 | 5.00 | 0.80 | 28.0-31.5 | ≥50 | 7.0-12.0 | 1.0-2.5 | 0.50 | 0.50 | |

| AWS Rules | 0.05 | 5.00 | 0.75 | 28.0-31.5 | Margin | 7.0-12.0 | 1.0-2.5 | 0.50 | 0.50 | |

| EXEMPLUM PENSI HABEO | 0.041 | 2.5 | 0.33 | 29.6 | 56.9 | 9 | 1.45 | 0.017 | 0.041 | |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | IMAPACT VALEO J/℃ | PROLATIO(%) | ||||

| GB/T REGULAE | 360 | 550 | - | 27 | ||||

| AWS Rules | - | 550 | - | 30 | ||||

| EXEMPLUM PENSI HABEO | 450 | 650 | - | 41.5 | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W* | 55-80 | 65-110 | 80-130 | ||||||||