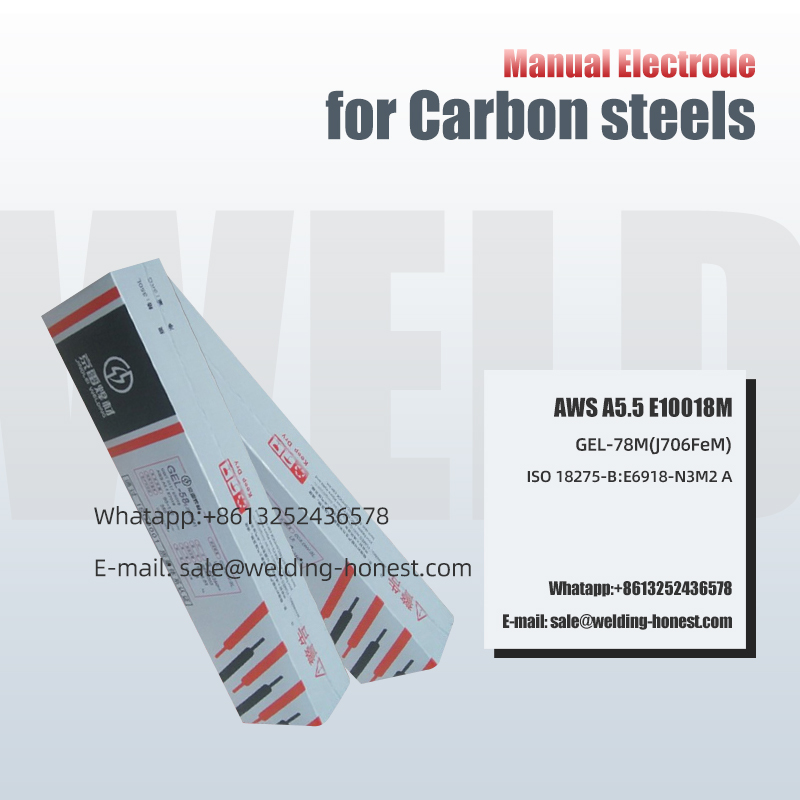

Princeps Carbon steels Manual electrode E9018-M fabricationis nexum

Applicationem

Eadem fortitudinis gradu admiscens ferro apta glutino.

Vexillum convenimus: GB/T32533 E6915-4M2P, AWS A5.5 E10015-D2 & A5.5M E6915-D2, ISO18275-A:E 62 5 Mn1NiMo B 4 2, ISO 18275-B: E6915-4M2 P.

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T REGULAE | 0.10 | 0.6-1.25 | 0.80 | 0.15 | 1.4-1.8 | 0.35 | 0.030 | 0.030 | 0.05 |

| AWS Rules | 0.10 | 0.6-1.25 | 0.80 | 0.15 | 1.4-1.8 | 0.35 | 0.030 | 0.030 | 0.05 |

| EXEMPLUM PENSI HABEO | 0.093 | 1.10 | 0.26 | 0.04 | 1.50 | 0.26 | 0.011 | 0.007 | 0.01 |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | HEATTREAMENT℃xh | IMAPACT VALEO J/℃ | PROLATIO(%) | ||||

| GB/T REGULAE | 540-620 | 620 | - | 27/-50 | 21 | ||||

| AWS Rules | 540-620 | 620 | - | 27/-50 | 24 | ||||

| EXEMPLUM PENSI HABEO | 605 | 700 | - | 90/-50 | 24 | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W* | 50-80 | 90-120 | 130-160 | - | |||||

Peculiaritas

620Mpa gradus summus vires gradus fortis durities ferrei pulveris humilis hydrogenii electrode.

Superficies globulus levis est, arcus stabilis est, adipiscing parvus est, gestiens facilis est, efficientia alta liquescens.

Humilis diffusio hydrogenii contentus, bonum rima resistentia, proprietates mechanicas stabiles.

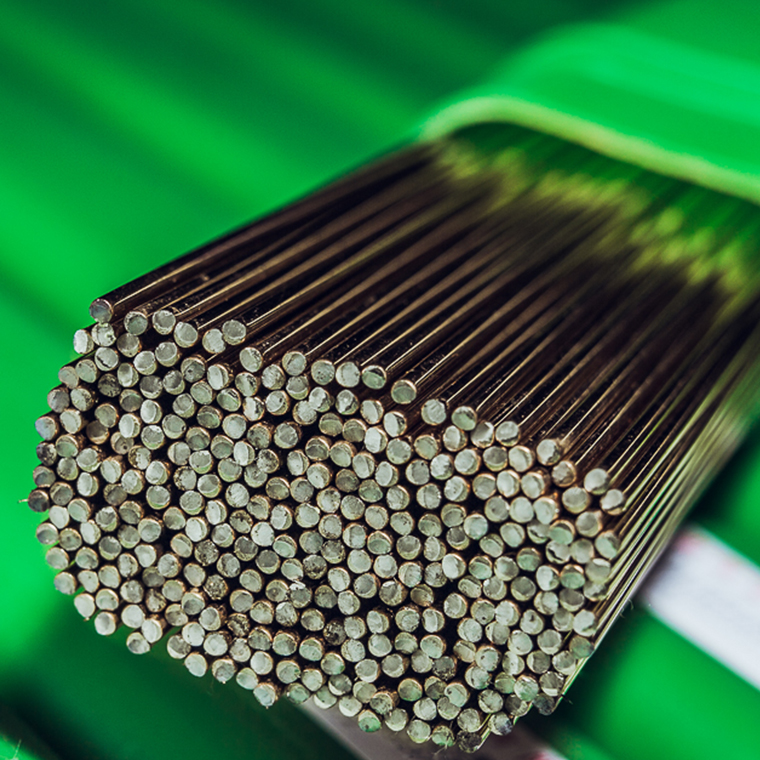

Monstra singula

Arcus stabilitas

Minus adipiscing

De nobis

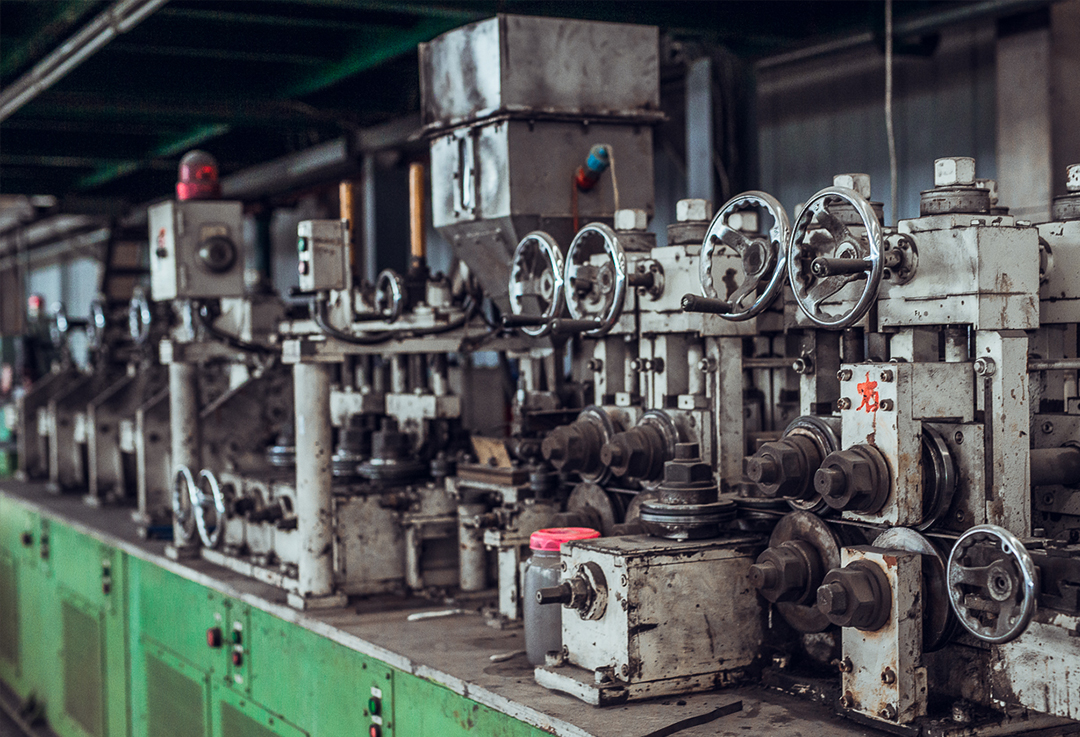

Factory fioor ostentationem

Applicationem causa

Sichuan Youjian Lunnan Base

Harbin Electric - Sanmen, Haiyang MSR

Ipsam officinam dirigentes

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T REGULAE | 0.10 | 0.6-1.25 | 0.80 | 0.15 | 1.4-1.8 | 0.35 | 0.030 | 0.030 | 0.05 |

| AWS Rules | 0.10 | 0.6-1.25 | 0.80 | 0.15 | 1.4-1.8 | 0.35 | 0.030 | 0.030 | 0.05 |

| EXEMPLUM PENSI HABEO | 0.093 | 1.10 | 0.26 | 0.04 | 1.50 | 0.26 | 0.011 | 0.007 | 0.01 |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | HEATTREAMENT℃xh | IMAPACT VALEO J/℃ | PROLATIO(%) | ||||

| GB/T REGULAE | 540-620 | 620 | - | 27/-50 | 21 | ||||

| AWS Rules | 540-620 | 620 | - | 27/-50 | 24 | ||||

| EXEMPLUM PENSI HABEO | 605 | 700 | - | 90/-50 | 24 | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W* | 50-80 | 90-120 | 130-160 | - | |||||

Epistulam tuam hic scribe et mitte nobis