Princeps Carbon steels Manual electrode E10018M fabricandi fabrica

Applicationem

Apta glutino RERUM respondentium vi gradus humilium admixtum altum roboris structurae ferro, ut machinae constructiones, etc.

Vexillum convenimus: GB/T32533 E6918-N3M2, AWS A5.5 E10018M & A5.5M E6918M, ISO18275-A:, ISO 18275-B: E6918-N3M2 A.

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T REGULAE | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| AWS Rules | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| EXEMPLUM PENSI HABEO | 0.093 | 1.54 | 0.33 | 0.02 | 1.85 | 0.38 | 0.013 | 0.006 | 0.002 |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | HEATTREAMENT℃xh | IMAPACT VALEO J/℃ | PROLATIO(%) | ||||

| GB/T REGULAE | 610-690 | 690 | AW | 27/-50 | 18 | ||||

| AWS Rules | 610-690 | 690 | AW | 27/-50 | 20 | ||||

| EXEMPLUM PENSI HABEO | 655 | 735 | AW | 85/-50 | 23 | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W* | 50-80 | 90-120 | 130-160 | - | |||||

Peculiaritas

Pulvis ferreus humilis hydrogenii potassium manu electrode, alta efficientia.

Arcus stabilis, tabulae parvae, coronae bonae, facile deiectae.

X-radius effectus est bonum, stabilium proprietatum mechanicarum.

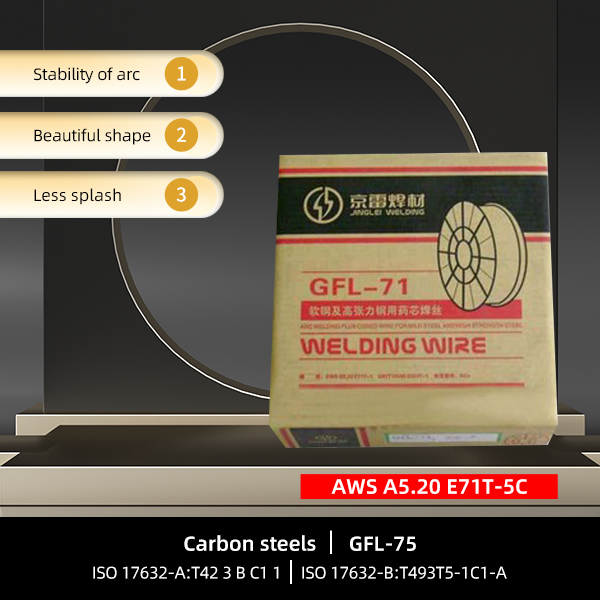

Monstra singula

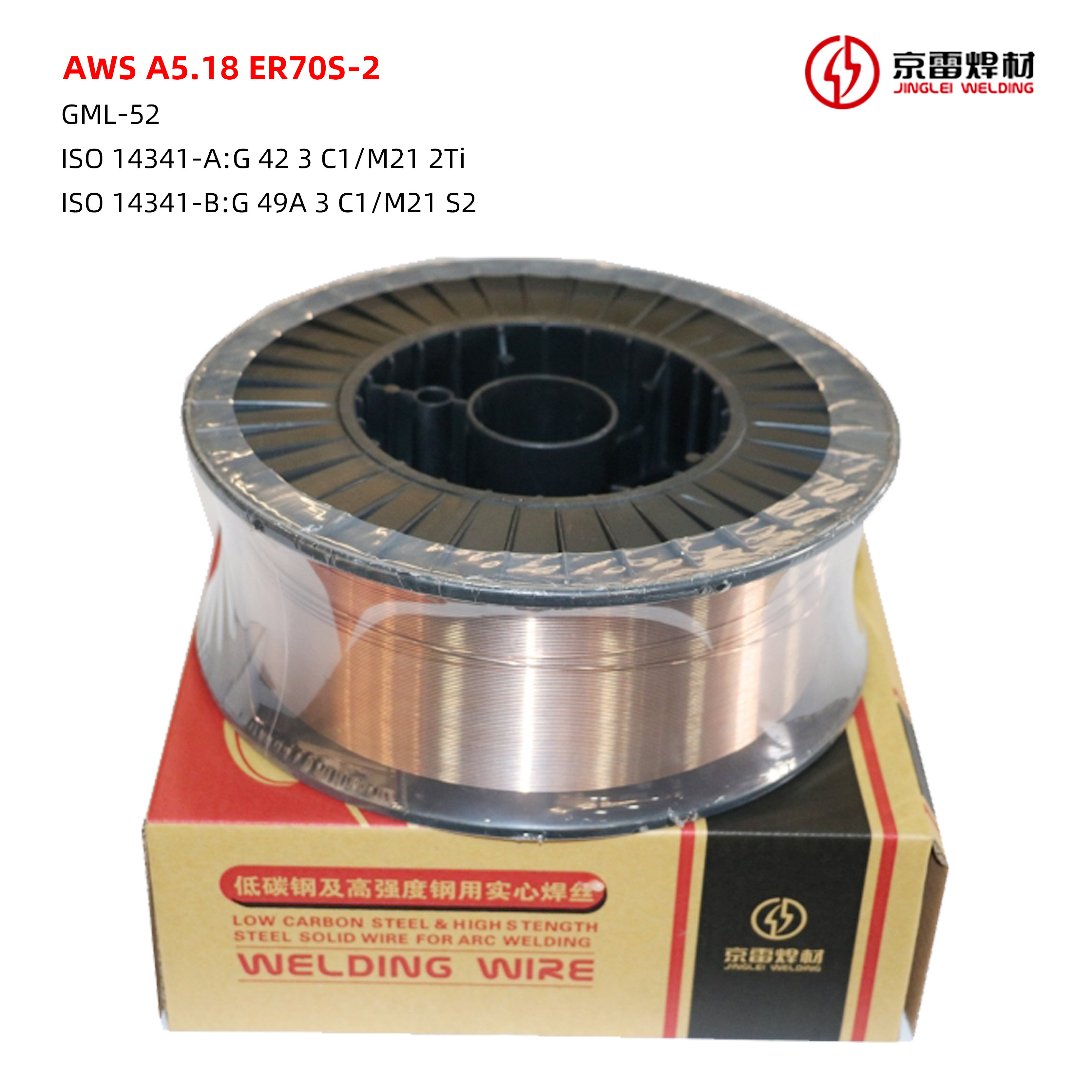

Pulchra figura

Pulchra figura

De nobis

Factory fioor ostentationem

Applicationem causa

300,000-ton contra ipsam Curabitur productio et at Tanker (FPSO)

308,000 talenta VLCC navis cruda

Ipsam officinam dirigentes

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T REGULAE | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| AWS Rules | 0.10 | 0.75-1.70 | 0.60 | 0.35 | 1.40-2.10 | 0.25-0.5 | 0.030 | 0.030 | 0.05 |

| EXEMPLUM PENSI HABEO | 0.093 | 1.54 | 0.33 | 0.02 | 1.85 | 0.38 | 0.013 | 0.006 | 0.002 |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | HEATTREAMENT℃xh | IMAPACT VALEO J/℃ | PROLATIO(%) | ||||

| GB/T REGULAE | 610-690 | 690 | AW | 27/-50 | 18 | ||||

| AWS Rules | 610-690 | 690 | AW | 27/-50 | 20 | ||||

| EXEMPLUM PENSI HABEO | 655 | 735 | AW | 85/-50 | 23 | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W* | 50-80 | 90-120 | 130-160 | - | |||||

Epistulam tuam hic scribe et mitte nobis