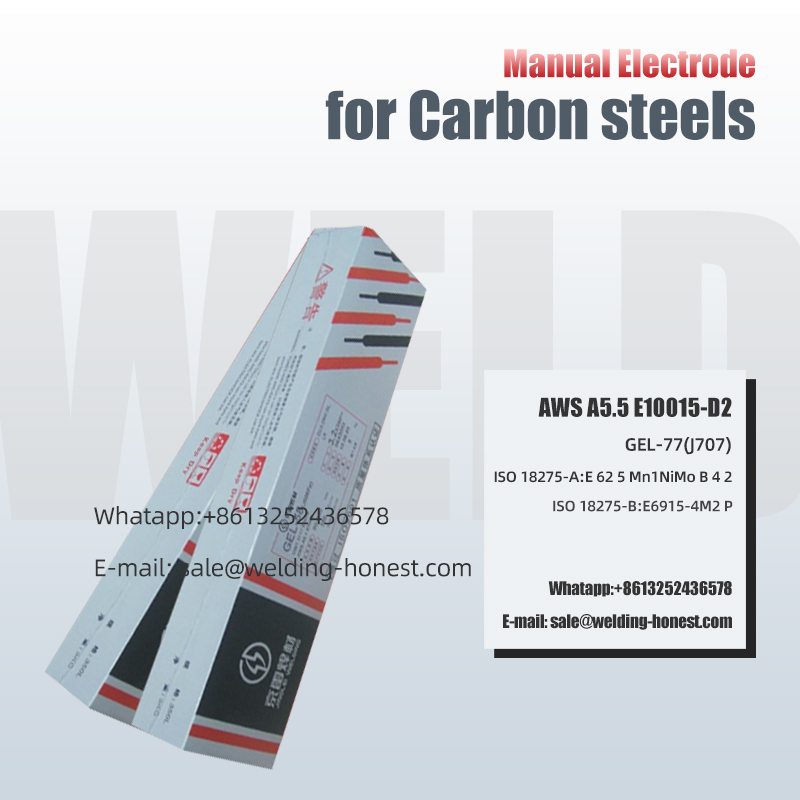

High Carbon Steels Manual Electrode E10015-D2 ore boat weld

Eadem fortitudinis gradu admiscens ferrum idoneum admiscuit glutino.

Vexillum convenimus: GB/T32533 E6915-4M2P, AWS A5.5 E10015-D2 & A5.5M E6915-D2, ISO18275-A:E 62 5 Mn1NiMo B 4 2, ISO 18275-B: E6915-4M2P.

Quid sunt?

moribus?

●Humilis sodium hydrogenii electrode, arcus stabilis, parva adipiscing, bonum formans.

●Securus desagging, X-ray perficientur est optimum.

●Bene rima resistit.

●Stabula mechanica.

Product Parameter

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| GB/T REGULAE | 0.15 | 1.65-2.00 | 0.60 | - | 0.90 | 0.25-0.45 | 0.030 | 0.030 |

| AWS Rules | 0.15 | 1.65-2.00 | 0.60 | - | 0.90 | 0.25-0.45 | 0.030 | 0.030 |

| EXEMPLUM PENSI HABEO | 0.093 | 1.84 | 0.42 | 0.02 | 0.80 | 0.40 | 0.013 | 0.008 |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | HEATTREAMENT℃xh | IMAPACT VALEO J/℃ | PROLATIO(%) | ||||

| GB/T REGULAE | 600 | 690 | 620*1 | 27/-50 | 14 | ||||

| AWS Rules | 600 | 690 | 620*1 | 27/-50 | 16 | ||||

| EXEMPLUM PENSI HABEO | 655 | 730 | 620*1 | 50/-50 | 23 | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W* | 50-80 | 90-120 | 130-160 | - | |||||

Vide in via

transportamus

●Motor transport

●Shipping

Lookat

nos wareouse

Incepta

nos involvunt

●Sina-Russia ante orientem

Nostra products

ad mundum

CHEMICAL COMPONET:

| ADMISSUS (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| GB/T REGULAE | 0.15 | 1.65-2.00 | 0.60 | - | 0.90 | 0.25-0.45 | 0.030 | 0.030 |

| AWS Rules | 0.15 | 1.65-2.00 | 0.60 | - | 0.90 | 0.25-0.45 | 0.030 | 0.030 |

| EXEMPLUM PENSI HABEO | 0.093 | 1.84 | 0.42 | 0.02 | 0.80 | 0.40 | 0.013 | 0.008 |

MACHINA proprietas:

| POSSESSIO | VICTORITAS (MPa) | PROLATIO VIS (MPa) | HEATTREAMENT℃xh | IMAPACT VALEO J/℃ | PROLATIO(%) | ||||

| GB/T REGULAE | 600 | 690 | 620*1 | 27/-50 | 14 | ||||

| AWS Rules | 600 | 690 | 620*1 | 27/-50 | 16 | ||||

| EXEMPLUM PENSI HABEO | 655 | 730 | 620*1 | 50/-50 | 23 | ||||

PARAMETERS WELDING RECOMMENDED:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W* | 50-80 | 90-120 | 130-160 | - | |||||

Epistulam tuam hic scribe et mitte nobis